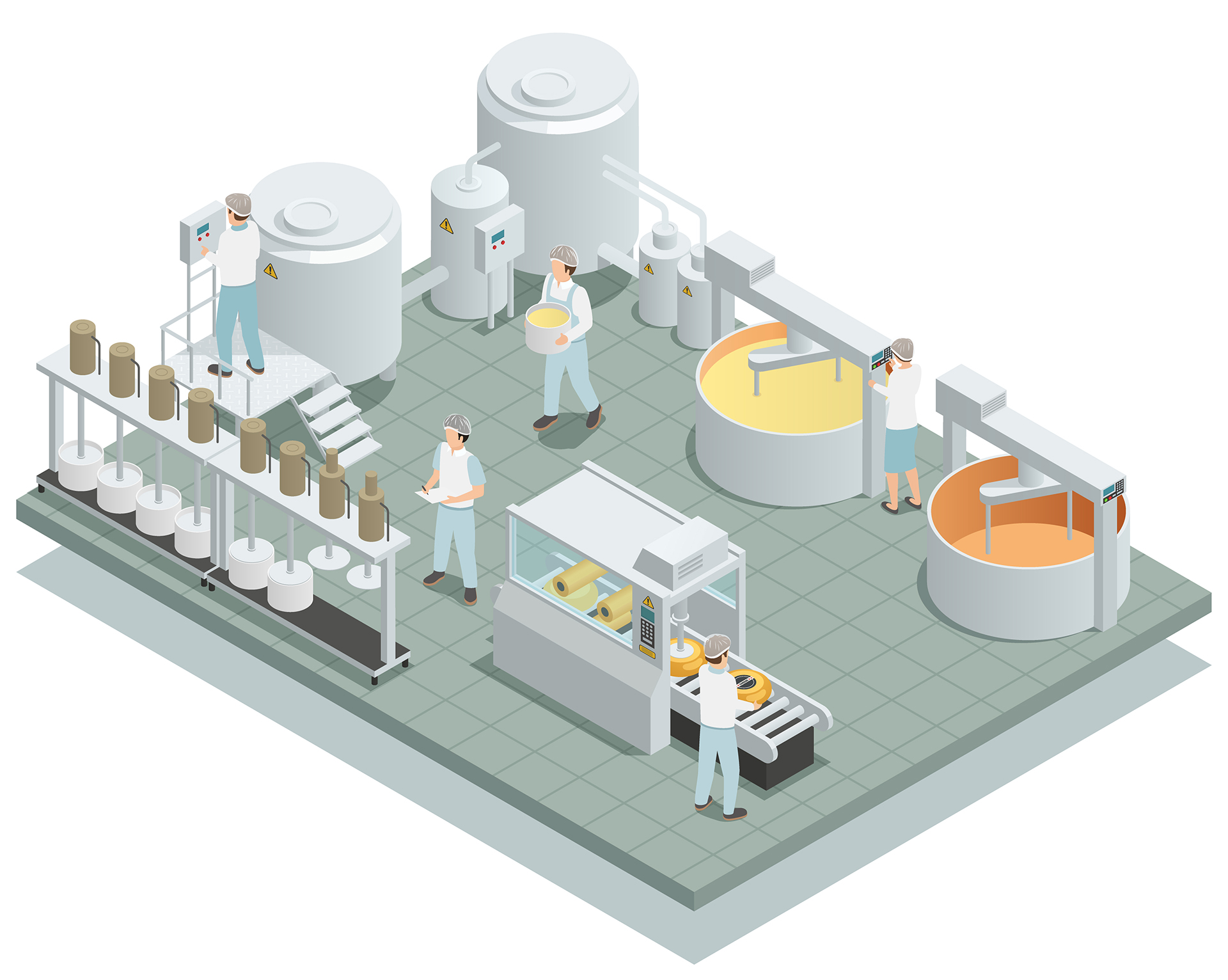

IoT in Manufacturing Industry

Making manufacturing more productive with lower costs

IntelliStride offers end-to-end IoT solutions to the Manufacturing Industry – large or small units. Some of the key issues troubling the industry are asset management, production inefficiencies, and supply chain management. If assets are not managed properly, it results in increased capital expenditure and poor resource planning. Similarly, inefficient inventory leads to either overstocking or a shortage of supply.

IntelliStride offers IoT solutions using world-class RFID technology for industrial manufacturers for better asset management and improved inventory accuracy. With IntelliStride IoT implementation you get data intelligence, increased production, reduced costs, efficient identification and tracking solutions.

The manufacturing use cases below are some of the IoT solutions we offer.

IoT in Manufacturing Use Cases

- Work-in-Process / Kanban / Replenishment / Re-work

- Monitor performance and maintenance of machines

- Spare parts and Finished product tracking in the plant, OEM plant (Production & Logistics) or at Dealers

- RTLS and Object Tracking

- People tracking for safety and productivity

Benefits of IoT solutions in Manufacturing industry

- Improved accuracy and efficiencies

- Better inventory tracking and reduction in costs

- Better routing information

- Better asset management and asset utilization

- Supply Chain management reduces costs

eKanBan

Core Application

- KanBan

- Contactless picking

Hardware Features

- ARU 2400, RRU 45x0 and up to 32

- smart-shelf antennas

- Cascadable with ©KRAI technology

- Selective read zones

- No shielding needed

Software & CrossTalk Features

- False-positive read filtering

- Configuration and monitoring

- Backend IT integration

Assembly Line

Core Applications

- Selective read zones for complex

tag orientation - Limited installation space

Hardware Features

- RRU 4xx0, ARU 3xx0 with diverse

antennas - Polarisation switch

©KRAI technology

Software & CrossTalk Features

- Unwanted reads filtering

- Configuration and monitoring

- Backend IT integration

Returnable Transport

Core Applications

- KanBan

- Contactless picking

Hardware Features

- ARU 2400, RRU 45x0 and up to 32

smart-shelf antennas - Cascadable with ©KRAI technology

- Selective read zones

- No shielding needed

Software & CrossTalk Features

- Configuration and monitoring

- False-positive read filtering

- Backend IT integration

Semiconductor Equipment Manufacturing with RFID and IoT: A Powerful Combination

The semiconductor industry relies on precision, efficiency, and tight control throughout the manufacturing process. Integrating RFID (Radio Frequency Identification) and IoT (Internet of Things) technologies offers significant benefits for semiconductor equipment manufacturers. Here's how:

Benefits of RFID:

- Enhanced Asset Tracking: RFID tags affixed to equipment can track location, status (active, idle, maintenance), and usage history. This improves asset utilization and simplifies maintenance scheduling.

- Improved Inventory Management: Track high-value tools, spare parts, and consumables using RFID tags. This reduces stockouts and ensures necessary items are readily available.

- Streamlined Production Workflow: Embed RFID tags in Front-Opening Unified Pods (FOUPs) used to transport wafers. This allows for automatic identification and real-time tracking within production lines, optimizing workflow and reducing errors.

- Compliance and Security: RFID tags can store calibration certificates and other critical data, ensuring regulatory compliance and equipment security.

Benefits of IoT:

- Real-time Equipment Monitoring: Sensors integrated with equipment can collect real-time data on performance parameters (temperature, vibration, power consumption). This allows for predictive maintenance, preventing downtime and optimizing equipment lifespan.

- Process Optimization: IoT sensors can monitor environmental conditions and integrate with equipment controls. This allows for automated adjustments to maintain optimal production conditions, improving yield and quality.

- Remote Diagnostics and Support: Real-time data from equipment can be transmitted to the cloud. Engineers can remotely diagnose issues, reducing downtime and maintenance costs.

- Data-Driven Decision Making: By collecting and analyzing data from equipment and processes, manufacturers can gain valuable insights to optimize production processes, improve efficiency, and make data-driven decisions.

Integration of RFID and IoT: - Combined Data Analysis: Combine data from RFID tags (location, status) with sensor data (performance) to gain a holistic view of equipment health and utilization.

- Automated Workflows: Trigger automated actions based on real-time data. For example, automatically order replacement parts when sensor data indicates low inventory.

Overall, by leveraging RFID and IoT technologies, semiconductor equipment manufacturers can achieve significant improvements in: - Production Efficiency

- Equipment Uptime

- Inventory Management

- Yield and Quality Control

- Predictive Maintenance

- Data-Driven Decision Making

With the emphasis on data-driven decisions, Artificial Intelligence: AI is driving a greater interest to further improve productivity and efficiency in operations, giving higher yield from the existing resources and assets.

CASE STUDY

Pallet Tracking Solution using RFID in Singapore

While RFID has existed for many years, latest developments have rendered is even more indispensable for implementing IoT solutions and shaping the...

How RFID is shaping the connected world?

Auto service processes can be improved using RFID technology with vehicle status tracking to provide better customer experience to car owners.

- Intellistride.com

- IoT Solutions

- Manufacturing